The Function of Fasteners and Machining in High-Quality Product Design

Browsing the World of Fasteners and Machining: Methods for Accuracy and Speed

In the elaborate world of bolts and machining, the pursuit for accuracy and rate is a perpetual difficulty that requires precise interest to information and critical planning. From recognizing the varied array of bolt types to selecting optimal materials that can endure extensive demands, each action in the process plays a pivotal role in accomplishing the wanted result.

Understanding Bolt Types

When selecting fasteners for a task, understanding the various kinds readily available is crucial for guaranteeing ideal efficiency and dependability. Bolts come in a large range of kinds, each created for particular applications and needs. Bolts are used with nuts to hold products together, while screws are versatile fasteners that can be utilized with or without a nut, depending on the application. Nuts, on the other hand, are inside threaded fasteners that friend with screws or bolts, providing a protected hold. Washing machines are important for distributing the tons of the fastener and stopping damages to the product being secured. In addition, rivets are irreversible fasteners that are perfect for applications where disassembly is not called for. Recognizing the distinctions between these bolt types is essential for choosing the right one for the job, guaranteeing that the link is solid, long lasting, and trusted. By selecting the ideal bolt type, you can enhance the efficiency and long life of your project - Fasteners and Machining.

Choosing the Right Materials

Recognizing the significance of selecting the right products is critical in ensuring the optimal efficiency and reliability of the picked fastener kinds reviewed formerly. When it pertains to bolts and machining applications, the product option plays an essential duty in identifying the general toughness, sturdiness, deterioration resistance, and compatibility with the designated environment. Various products supply varying residential properties that can dramatically impact the performance of the fasteners.

Usual materials made use of for bolts include steel, stainless steel, brass, aluminum, and titanium, each having its special strengths and weak points. Steel is renowned for its high toughness and toughness, making it suitable for a wide array of applications. Choosing the ideal material includes considering elements such as strength demands, ecological conditions, and spending plan constraints to guarantee the preferred performance and long life of the fasteners.

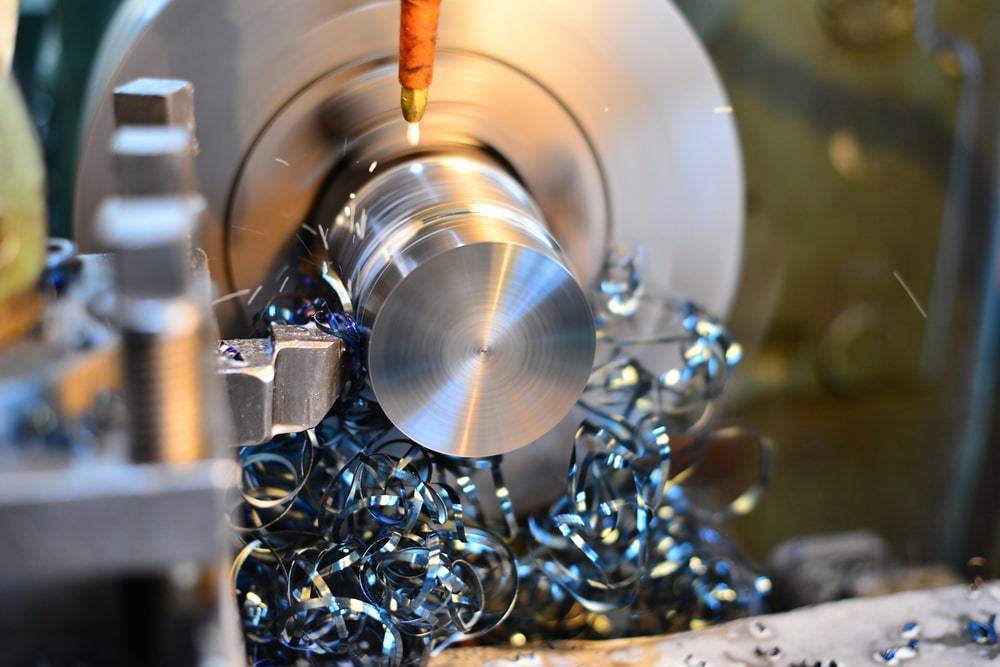

Accuracy Machining Techniques

Along with CNC machining, various other precision techniques like grinding, transforming, milling, and exploration description play crucial duties in bolt manufacturing. Grinding assists achieve great surface area finishes and limited dimensional resistances, while turning is often made use of to develop cylindrical components with precise sizes. Milling and drilling operations are essential for forming and producing openings in fasteners, guaranteeing they fulfill precise requirements and function correctly.

Enhancing Speed and Efficiency

To enhance fastener production procedures, it is essential to simplify operations and carry out reliable approaches that complement precision machining techniques. One essential approach for enhancing rate and performance is the execution of lean production principles. By lowering waste and concentrating on continual enhancement, lean Get More Information practices aid optimize and remove bottlenecks process. In addition, buying automation technologies can substantially enhance production rate. Automated systems can handle repeated tasks with precision and speed, permitting workers to concentrate on more complicated and value-added tasks. Adopting Just-In-Time (JIT) stock administration can likewise enhance performance by ensuring that the best materials are offered at the right time, reducing excess stock and lowering preparations. Additionally, promoting a culture of partnership and communication among employee can improve general performance by advertising transparency, analytic, and innovation. By integrating these methods, producers can attain an equilibrium between speed and accuracy, ultimately enhancing their one-upmanship in the bolt industry.

Top Quality Control Measures

Applying rigorous high quality control steps is critical in making sure the integrity and uniformity of bolt items in the manufacturing procedure. Quality assurance actions incorporate various stages, beginning with the option of resources to the final inspection of the finished fasteners. One fundamental aspect of quality assurance is conducting detailed product inspections to verify compliance helpful resources with requirements. This includes evaluating elements such as material strength, longevity, and composition to guarantee that the fasteners fulfill sector requirements. Furthermore, keeping an eye on the machining processes is vital to maintain dimensional accuracy and surface area finish high quality. Utilizing sophisticated technology, such as computerized evaluation systems and accuracy measuring tools, can boost the accuracy and efficiency of top quality control treatments.

Routine calibration of equipment and equipment is imperative to preserve uniformity in manufacturing and make certain that bolts fulfill the required resistances. Implementing stringent protocols for recognizing and resolving non-conformities or defects is crucial in protecting against substandard products from entering the market. By developing a thorough quality control structure, producers can promote the reputation of their brand and provide bolts that fulfill the highest possible standards of performance and sturdiness.

Conclusion

In the elaborate realm of fasteners and machining, the mission for precision and speed is a perpetual difficulty that requires thorough focus to information and critical preparation. When it comes to bolts and machining applications, the product choice plays a critical duty in establishing the total toughness, durability, corrosion resistance, and compatibility with the intended atmosphere. Precision machining includes various advanced approaches that make certain the limited tolerances and specs required for fasteners.In enhancement to CNC machining, various other precision techniques like grinding, transforming, milling, and exploration play crucial functions in fastener manufacturing.To maximize fastener production procedures, it is crucial to enhance operations and implement reliable methods that match precision machining strategies.